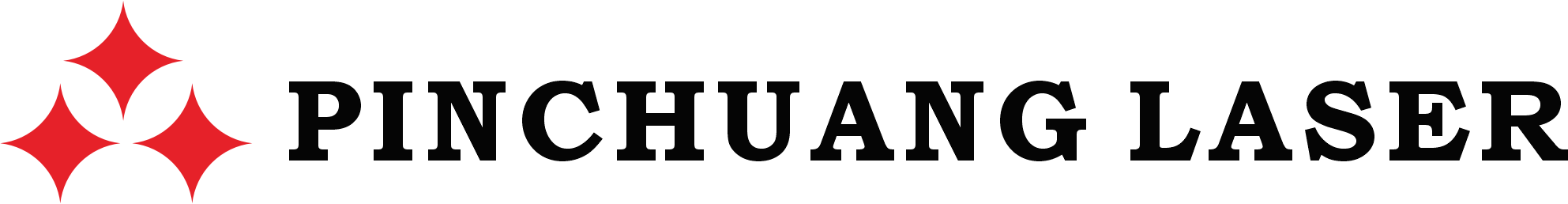

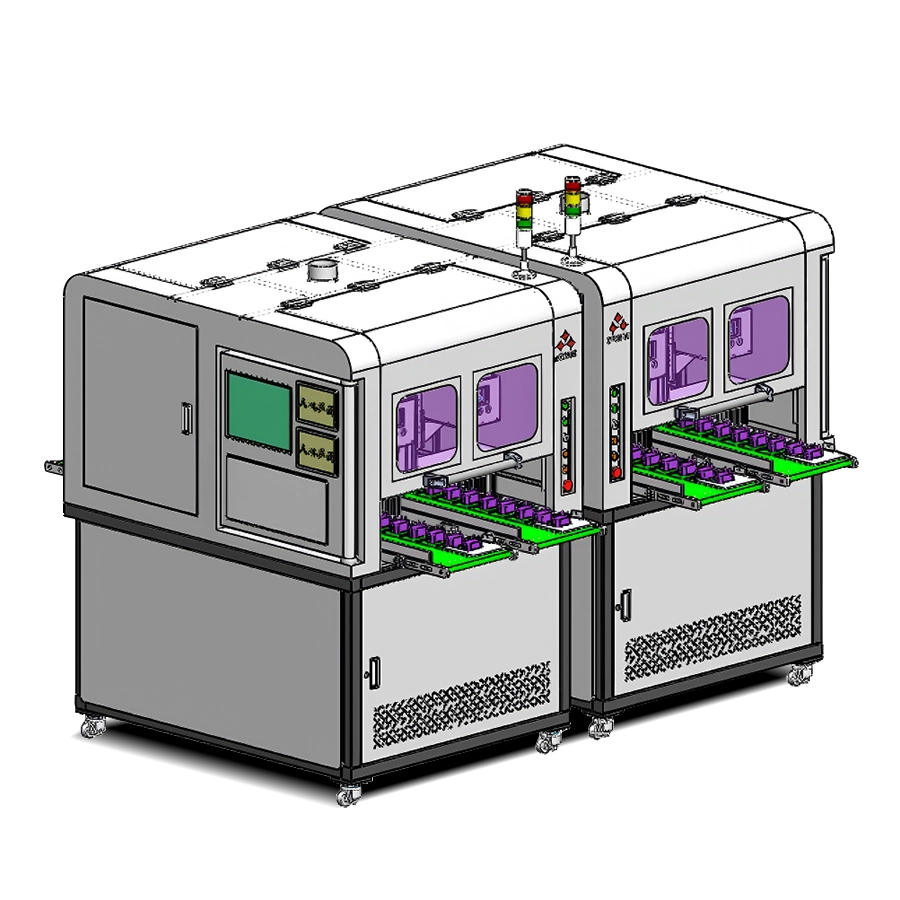

Fully automatic adapter laser marking Specialized equipment.

The industry-leadingfully automatic adapter-specific processing and testing all-in-one machine. This equipment can solve the problem of adaptertraceability,improve the processing process;establish traceability hair difficulty, improve the production management system;replace manual inspection, reduce labor costs and improve product quality; and solve the problem of laserengravingfrom the source such as wrongradium,less radium and duplicate 2D code.

Product Advantages

01

- vision inspection system 10 million vision system,independent research and development,professional customized solutions forcustomers,scanning productQR code,processing and inspection data can be quickly docked with MESfortraceability queries

- can be connected to the internal management network, access to workstation information codes, access to variable information,automatic data generation radium engraving,access toinspection data, upload storage.

- Adopt visual positioning processingto ensure processing accuracy

- Can detect laserengraving defects, such as missing word,broken word,angle,position offset and other defects

- safe quality assurance,can NG mark the defective products and refuse the outflow of defective products.

- Fast processing speed with dual workstations

Product Specifications

03

| Item | Specification Parameters | |

|---|---|---|

| Lasser Wavelength | 355nm | |

| Average Power | 3w/5w/10w | |

| Repetition Frequency | 20KHz-150KHz | |

| Marking/Engraving Range | 100mm*100mm/150mm*150mm(optional) | |

| Standard Working Distance | 0.02mm | |

| Scanning Speed | ≤7000mm/s | |

| Minimum Line Width | 0.02mm | |

| Minimum Character Size | ±0.05mm | |

| Maximum machine power | 1.5kw | |

| cooling method | Water cooling | |

| Power supply | 220V/single-phase/50Hz/10A | |

| Ambient Temperature | 15~35°C,if out ofrange, air conditioning is required | |

| Overall Dimension | Ordinary version 800*600*1500mm/standard version 1200*660*1600mm | |