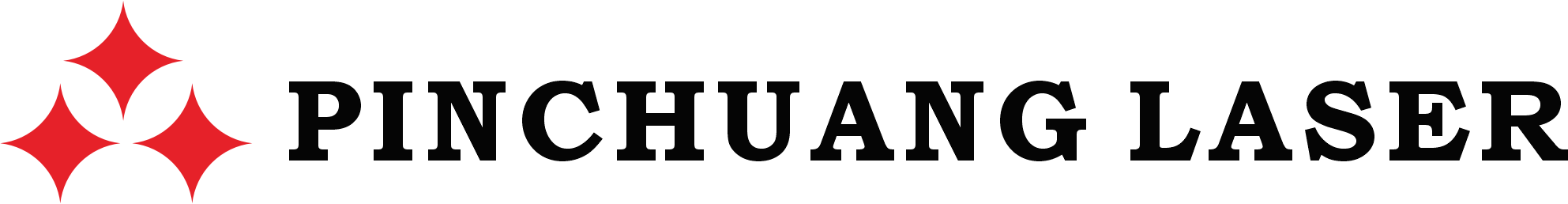

Dual-head CO2 laser peeling machine

The CO2 laser stripping machine is a model specifically designed for OTB/IO wires, and is used to remove residual insulation after precision stripping of metallic and non-metallic wires.

This equipment can remove residual insulation layers from the surface of wires with high precision and efficiency, and is widely used in high-end wires, precision electronic components, communication cables, automotive cables and other fields.

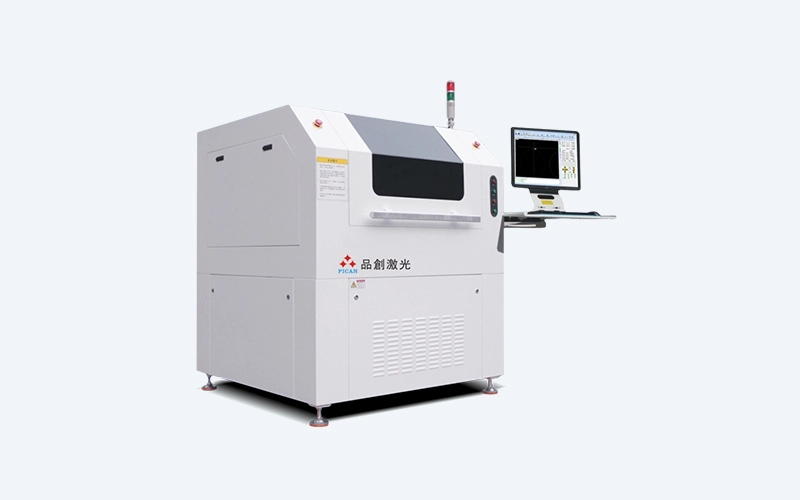

Product Advantages

01

- High precision and non-destructive: Non-contact laser processing causes zero damage to precision wires and perfectly removes residual insulation layers.

- Dual-head high efficiency: Dual workstations work synchronously or alternately, doubling production efficiency.

- Wide applicability: Compatible with various materials on-site, easily handling various complex line types.

- Stable and reliable: Simple to operate, consistent performance, effectively improving product yield and quality.

Sample Show

02

Product Specifications

03

| Item | Specification Parameters | |

|---|---|---|

| Lasser Wavelength | 9.3um | 10.6um |

| Laser power | 30W/60W/100W/150W (optional) | |

| Pulse frequency | 0-25KHz | |

| Cutting Range | 110×110mm | |

| Beam divergence angle | <8.0mrad | |

| Beam quality (M2) | <1.2 | |

| Beam size | 1.8 ±0.2mm | |

| working temperature | 5~40℃ | |

| cooling method | Air cooling/Water cooling | |

| power supply | 220V 50Hz/60Hz | |

| Machine power | 6200W | |

| Overall Dimension | 700mm (L) × 1500mm (W) × 1820mm (H) (excluding tri-color lights) | |