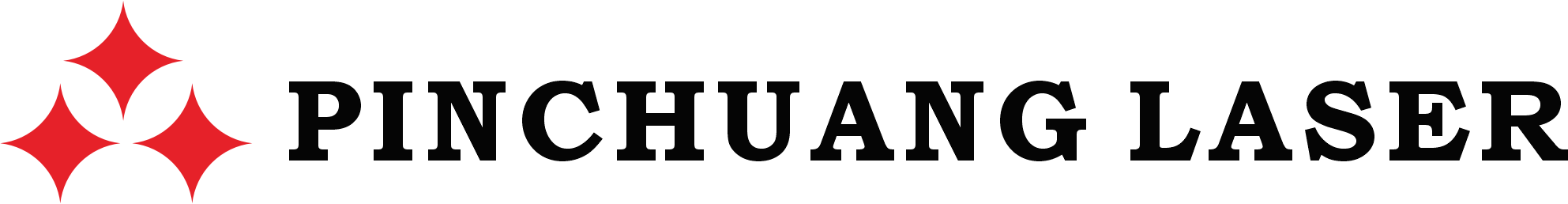

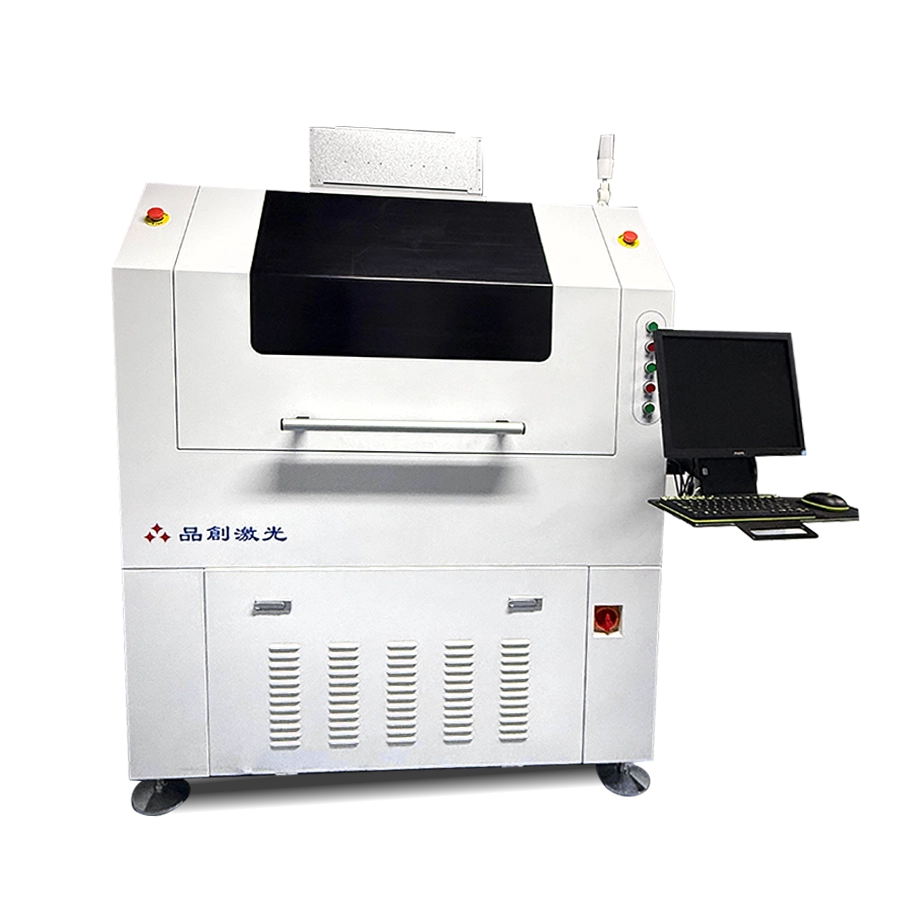

FPC Fully Automatic Ultraviolet Picosecond Laser Cutting Machine

The FPC fully automated ultraviolet picosecond laser cutting machine is designed for precision cutting and marking of precision components such as flexible circuit boards. The equipment integrates a high-power imported laser and a fully closed-loop magnetic levitation platform, combined with CCD target positioning and a grating system, to achieve micron-level processing accuracy. It supports online editing, QR code numbering, and galvanometer self-calibration, ensuring efficient, flexible, stable, and reliable production, significantly improving the automation level and product yield of high-end electronic manufacturing.

Product Advantages

01

- High-performance laser source: It adopts a high-quality imported laser with excellent beam quality, stable power output, and effective suppression of thermal effects during processing.

- Micrometer-level positioning accuracy: Equipped with a high-precision grating system, it achieves repeatability and processing accuracy far exceeding conventional standards.

- Intelligent sequence labeling: Integrates QR code labeling function, supports automatic serial numbers of up to 36 digits, and meets the needs of precise traceability.

- Real-time interactive control: It has online preview, real-time measurement and editing functions, which greatly improves the ease of operation and processing efficiency.

- Intelligent visual positioning: Equipped with a CCD vision system, it can automatically identify and accurately locate any complex shape.

- One-click quick calibration: The galvanometer system supports operator self-calibration, significantly reducing downtime and lowering maintenance costs.

- Fully Closed-Loop Intelligent Control Platform: The motion platform is under fully closed-loop control, and all processing parameters and process data are recorded in real time.

- Long-term stable operation: The core moving parts adopt magnetic levitation linear motors, which have no physical wear and tear, ensuring long-term stability and ultra-long lifespan of the equipment.

Sample Show

02

Product Specifications

03

| Item | Specification Parameters |

|---|---|

| Lasser Wavelength | 355nm |

| Laser power | >30W |

| pulse width | <15ps |

| Repetition Frequency | 100kHz-2MHz |

| Single pulse stability | <2%RMS |

| Spot mode | TEM00(M² <1.2) |

| Spot roundness | >90% |

| Beam divergence angle | <0.2mrad |

| average power stability | <1%RMS |

| Single frame cutting range | 45mmx45mm |

| Minimum focused spot of laser | 25um |

| Maximum working range of laser cutting | 500*600mm |

| Laser cutting speed | Adjustable from 100mm/s to 3000mm/s |

| Power supply for the whole machine | 3.5KW/AC380V or AC220V/50Hz |

| Ambient Temperature | 25±2℃ |

| Ambient humidity | Rh62±7% (no obvious condensation) |

| Machine dimensions/weight | 1400*1450*1800mm (excluding monitor) / 1500kg |