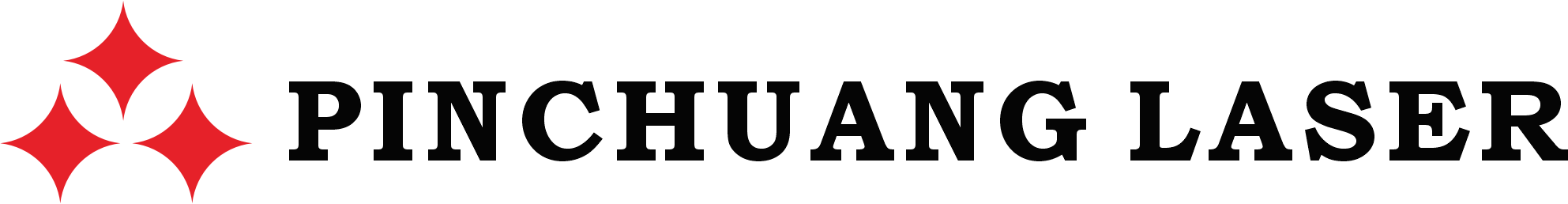

QR code automatic marking system

This system is a fully automated laser marking solution specifically designed for industrial traceability applications. It integrates a 10W UV laser source with an automatic vibratory bowl feeding and unloading mechanism, specializing in engraving high-precision, permanent QR codes on a wide range of metal product surfaces. The core value of the system lies in the exceptional durability of the marked QR codes. In addition to being clear and aesthetically refined, the markings offer outstanding corrosion resistance, successfully withstanding rigorous 24-hour continuous salt spray testing without rusting or oxidation. This ensures that traceability information remains readable and reliable throughout the entire product lifecycle. Featuring high stability and fully unmanned operation, the system is an ideal solution for enhancing production automation and product quality. It is widely used in high-end manufacturing sectors such as precision electronics, automotive components, and medical devices.

Product Advantages

01

- Permanent marking: 10W ultraviolet laser, cold light processing does not damage the workpiece, and the marking is clear and permanent.

- Extremely reliable: The QR code has passed a 24-hour salt spray test, is corrosion-resistant, and will not rust.

- Fully automated operation: The vibratory feeder automatically loads and unloads materials, enabling unmanned and efficient production.

Sample Show

02

Product Specifications

03

| Item | Specification Parameters |

|---|---|

| Lasser Wavelength | 355nm |

| Laser power | 5W/10W (optional) |

| Marking range | 100mm*100mm / 150mm*150mm (optional) |

| pulse width | <15ns |

| Laser adjustment indicator light | Visible light (red) |

| Laser output stability | <3% |

| Engraving line speed | ≤7000mm/s |

| Minimum Line Width | 0.02mm |

| Positioning accuracy | 0.05mm |

| cooling method | Water cooling |

| Power supply | 220V±5%, 50Hz/16A |

| Overall Dimension | 1000mm(L)×1000mm(W)×2000mm(H) |

| Ambient Temperature | 0~40°C,if out ofrange, air conditioning is required |

| Air source | 0.6~0.8MPa |