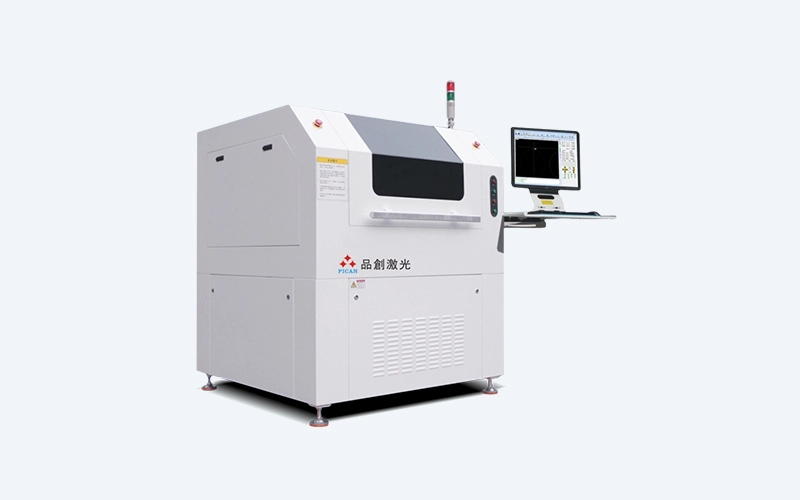

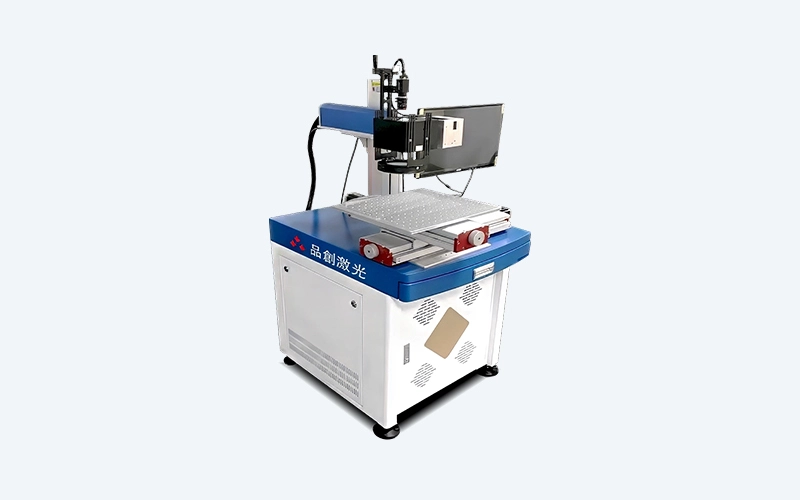

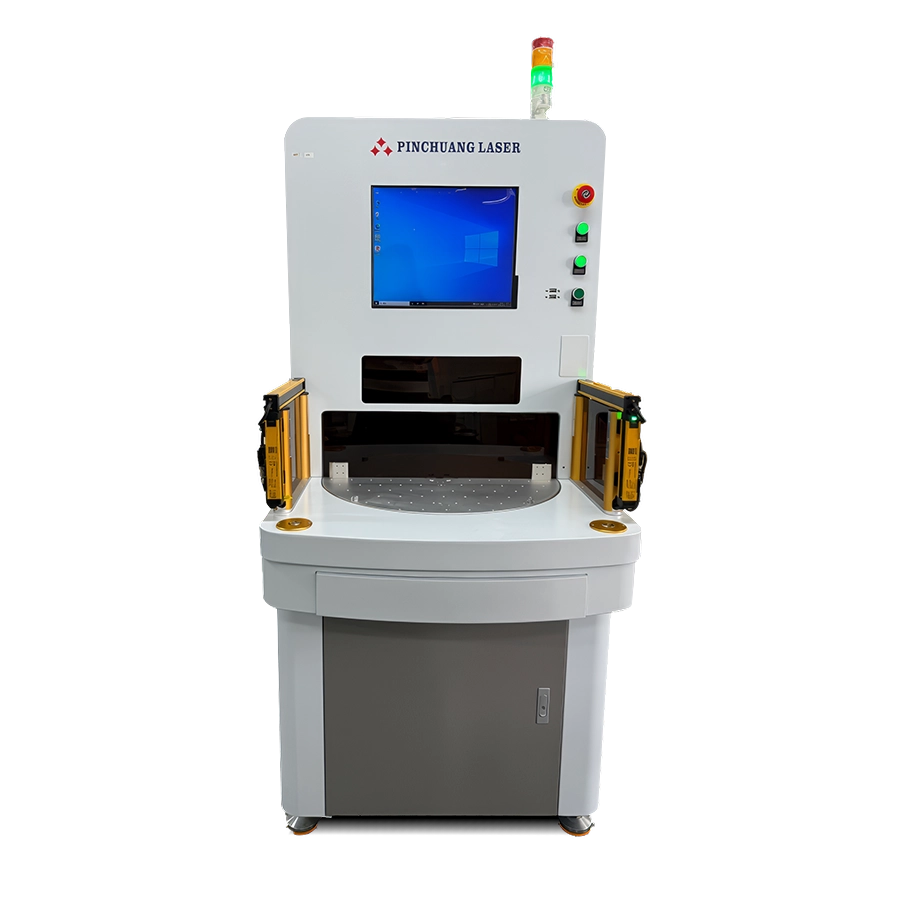

Two-station fiber laser marking machine

This equipment is a highly efficient automated marking solution that integrates a dual-station rotary table and a high-performance fiber laser. Through alternating operation of the two stations, loading/unloading and laser marking are performed simultaneously, minimizing downtime and significantly improving production efficiency.

The equipment is designed for permanent and clear marking on various material surfaces, such as QR codes, logos, text, and serial numbers. It features high marking accuracy, high speed, and stable operation, making it particularly suitable for small- to medium-batch continuous production needs in industries such as electronic components and hardware tools.

Product Advantages

01

- Increased efficiency: The dual-station turntable design enables simultaneous loading and unloading and laser marking, seamlessly connecting the processes and effectively doubling production efficiency.

- Mark Excellence: Equipped with a high-performance fiber laser, it can engrave permanent, clear, and beautiful QR codes, logos, and text on various metals and most non-metallic materials.

- Stable and durable: The fiber laser light source has a long lifespan, the whole machine operates stably and reliably, and can withstand high-intensity continuous operation, ensuring the smooth operation of the production line and the product yield.

Sample Show

02

Product Specifications

03

| Item | Specification Parameters |

|---|---|

| Lasser Wavelength | 1064nm |

| Laser power | 20W/30W/60W (optional) |

| Marking range | 100mm*100mm / 150mm*150mm (optional) |

| pulse width | 2-500ns |

| Frequency adjustment range | 1kHz-4000kHz |

| Power adjustment range | 0-100% |

| Output power instability | <5% |

| Beam quality M² | <1.8 |

| polarization direction | random |

| cooling method | Air cooling |

| Power supply | 220V±5%, 50Hz/16A |

| Overall Dimension | 1440mm(L)×760mm(W)×1995mm(H) |

| Ambient Temperature | 0~40°C,if out ofrange, air conditioning is required |