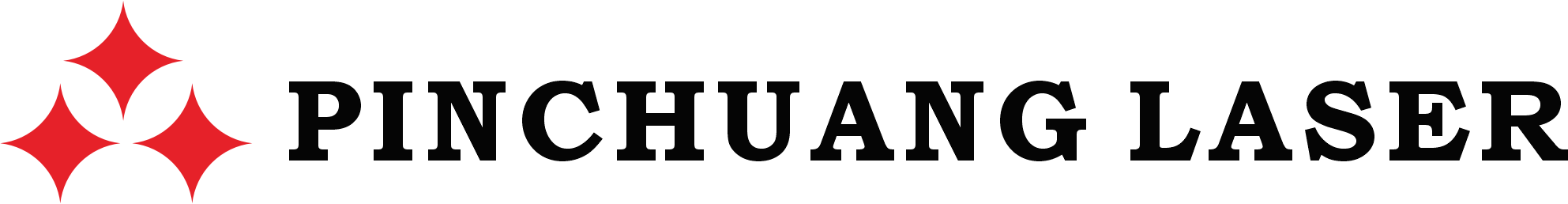

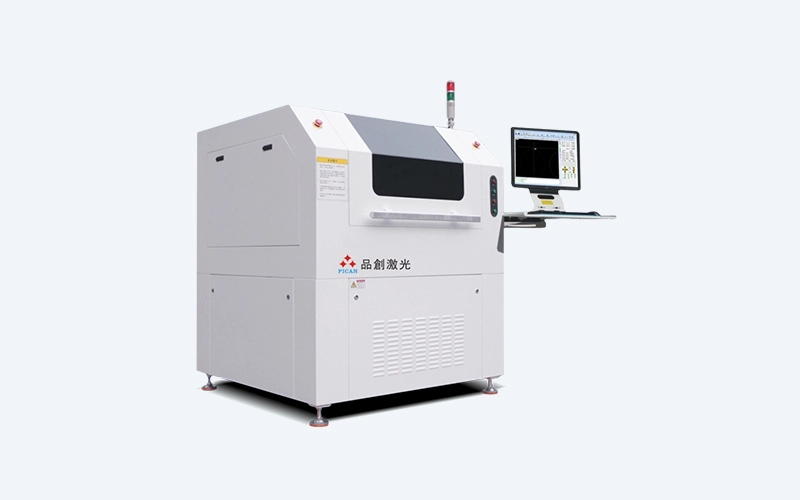

Adaptive vision laser processing system

This system integrates high-precision vision CCD and laser marking technology, enabling fully automated operation on an assembly line. The vision system intelligently captures and automatically compensates for product positional deviations, achieving dynamic and precise alignment and marking. It completely eliminates reliance on fixed fixtures, possesses extremely high production flexibility, and provides efficient and reliable automated marking solutions specifically for industries such as precision parts and electronic components.

Product Advantages

01

- Intelligent visual positioning: Built-in high-precision CCD vision system can automatically identify and dynamically compensate for product position deviations to achieve precise alignment.

- Fully automated and efficient operation: Combined with the production line, it realizes automatic feeding, positioning, marking and unloading, greatly reducing manual intervention and improving production efficiency.

- Exceptional production flexibility: Eliminates reliance on fixed fixtures, can quickly adapt to workpieces of different sizes and shapes, and easily handle mixed-line production.

- Stable and reliable processing: Ensure high consistency and permanent, clear labeling for every product during continuous assembly line operations, guaranteeing a high yield rate.

Sample Show

02

Product Specifications

03

| Item | Specification Parameters |

|---|---|

| Lasser Wavelength | 355nm |

| Laser power | 5W/10W (optional) |

| Pulse frequency | 30-150KHz |

| Marking range | 100mm*100mm / 150mm*150mm (optional) |

| pulse width | <15ns |

| Output power instability | <3% |

| Engraving depth | ≤0.4mm |

| Engraving line speed | ≤7000mm/s |

| Minimum Line Width | 0.02mm |

| Repeat Accuracy | ±0.003mm |

| Minimum characters | 0.3mm |

| cooling method | Water cooling |

| Power supply | 220V±5%, 50Hz/16A |

| Overall Dimension | 800mm(L)×600mm(W)×1500mm(H) |

| Ambient Temperature | 0~40°C,if out ofrange, air conditioning is required |