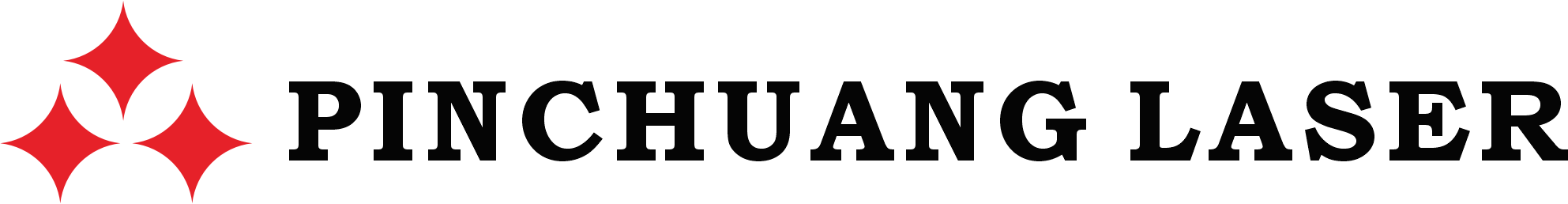

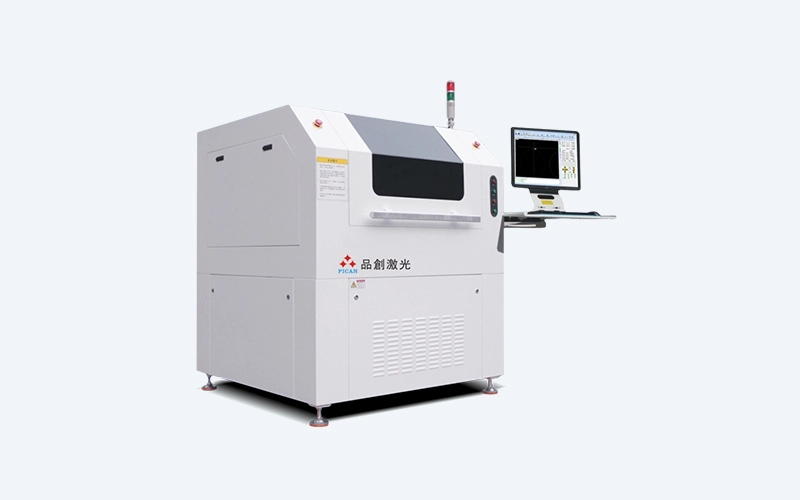

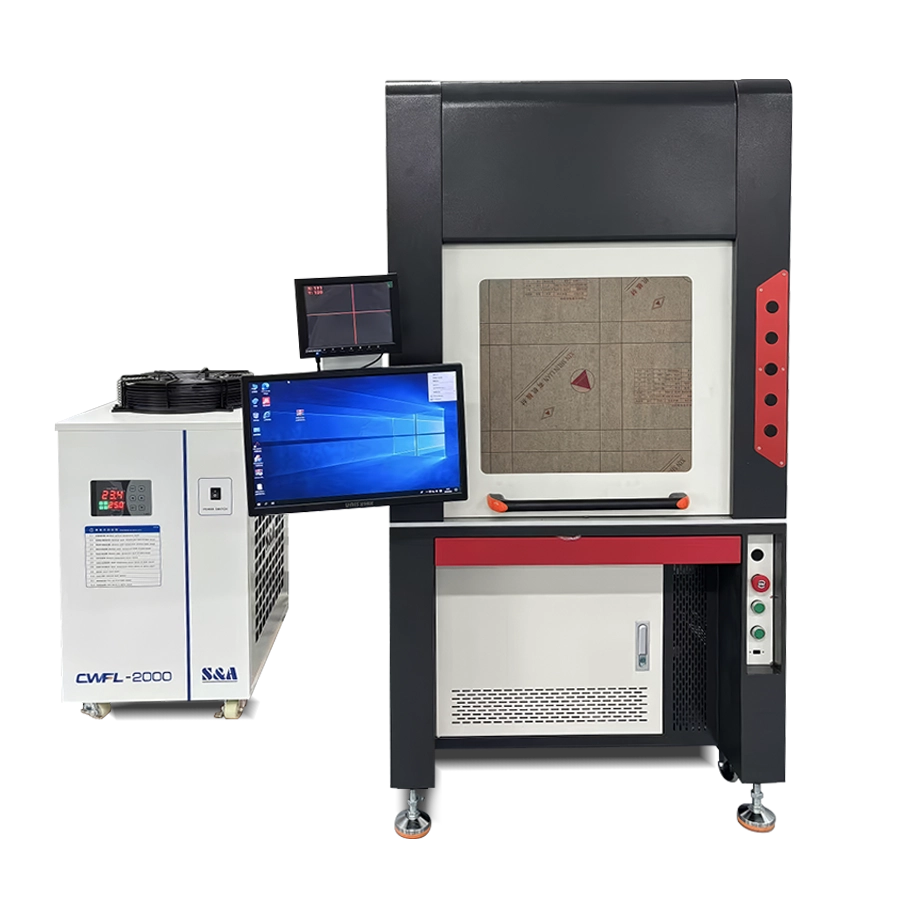

Continuous fiber laser welding system

1、Controlled by PC,assisted by special software, easy to learn and use,the workpiece can make plane trajectory movement, welding any point,straight line, circle, square orany plane figure composed of straight line and circular arc.

2、CCDLCD monitoring system,according to the red light indication can clearly observe the positioning of the product and the welding effect.

3、Relative to the traditional welding difficult to access parts,Non-contact welding can beimplemented,with greater flexibility.

Product Advantages

01

- Excellent laser beam quality,fast welding,solid and beautiful welding points, we provide users with efficient welding works.

- High electro-optical conversion rate, low energy consumption,no consumables,smallsize,long-term use can save a lot of processing costs forusers.

- It can be processed continuously and stably for24hours to meet the needs ofindustrial mass production and processing.

- Compared with the same powerYAG laser,it has the characteristics of deep welding depth and good elding strength.

Sample Show

02

Product Specifications

03

| Item | Specification Parameters |

|---|---|

| Lasser Wavelength | 1064nm |

| Average Power | 500W/1000W/2000W/3000W |

| Output poweradjustment range(%) | 1-100% |

| Output beam quality(fiber core diameter) | 20/50/100μm(optional) |

| Maximum modulation frequency | 1-50kHz(adjustable) |

| Lasser Output mode | Continuous/modulated |

| Weldinghead | Collimation head/oscillation head/vibration lens(optional) |

| Maximum machine power | 3kw |

| Repeated movement accuracy of the working table | ±0.05mm |

| cooling method | Air cooling/Water cooling |

| Input Voltage | 220VAC/50Hz/60Hz |

| Overall Weight | 234.5KG |

| Overall Dimension | 880mmx1000mmx1800mm |