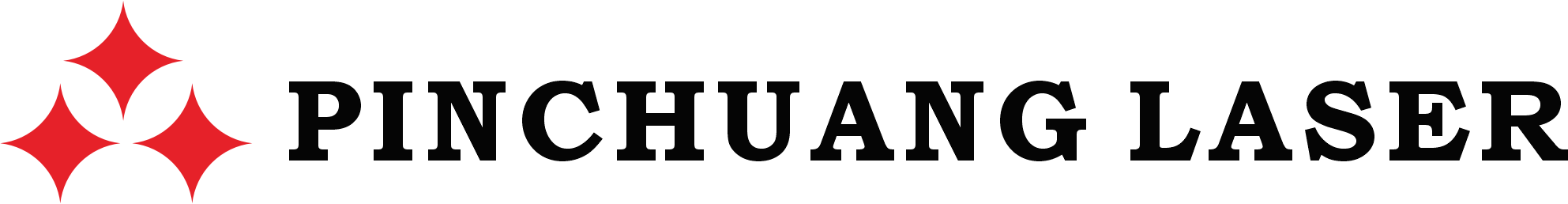

Four-station laser welding system

The four-station laser welding system adopts a rotary multi-station platform design, enabling synchronous cyclical operations of loading, welding, inspection, and unloading, significantly improving production cycle time and efficiency. Equipped with a high-performance fiber laser source, the system offers precise and controllable heat input, allowing for precision welding of thin materials and highly reflective metals, resulting in aesthetically pleasing welds and minimal workpiece deformation. The equipment boasts a high degree of automation integration and a compact structure, making it suitable for the mass automated production needs of industries such as new energy and 3C electronics.

Product Advantages

01

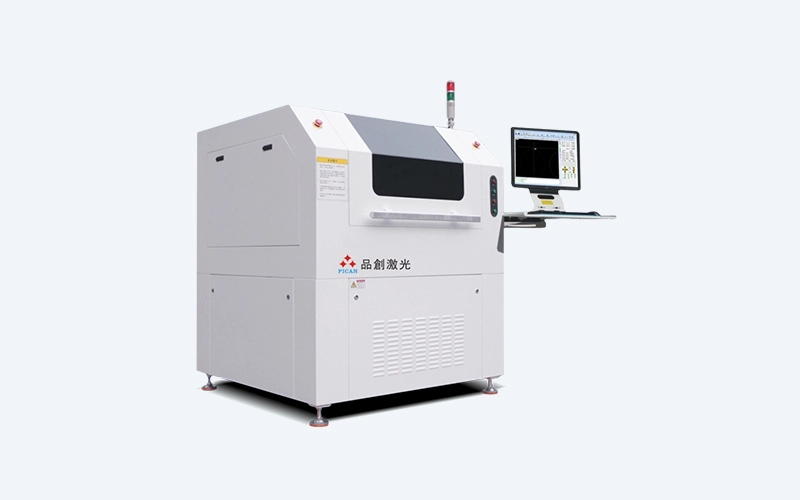

- Highly efficient parallel production: The four-station rotary design enables simultaneous loading, unloading, welding, and inspection processes, significantly improving production efficiency and cycle time.

- Full-process automation: Integrating automatic loading and unloading with a vision system, it achieves unmanned operation, stable operation, and reduces reliance on manual labor and errors.

- Flexible production line: It adopts a modular and standardized interface design, which can flexibly connect to different production processes and management systems and quickly respond to diverse production needs.

Product Specifications

03

| Item | Specification Parameters | |

|---|---|---|

| Lasser Wavelength | 1080nm±5nm | 10.6um |

| Laser power | 150W/200W/300W (optional) | |

| maximum pulse energy | 15J | |

| Power adjustment range | 10-100% | |

| pulse width | 0.01-50ms | |

| Repetition Frequency | 1-5000Hz | |

| Repeat Accuracy | ±0.01mm | |

| Minimum spot | 0.1mm | |

| cooling method | Air cooling | |

| power supply | Two-phase 220V±5%, 50Hz, 16A | |

| Machine power | 3000W | |

| Overall Dimension | 1440mm(L)×760mm(W)×2055mm(H) | |