NEWS

Corporate News, Industry Information

Intelligent Manufacturing Drives Medical Industry Upgrades

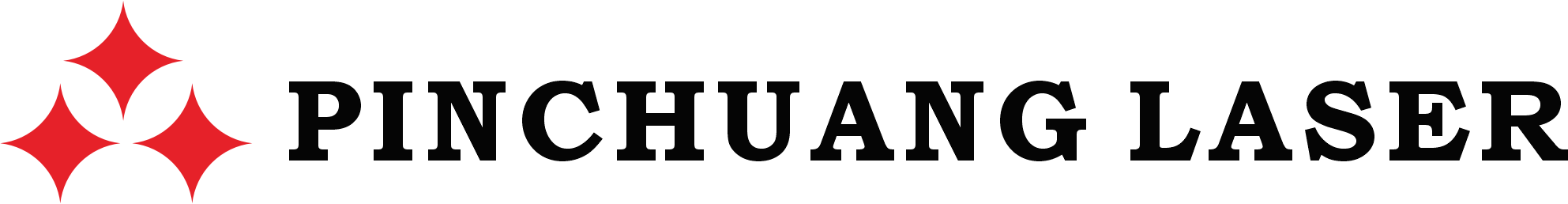

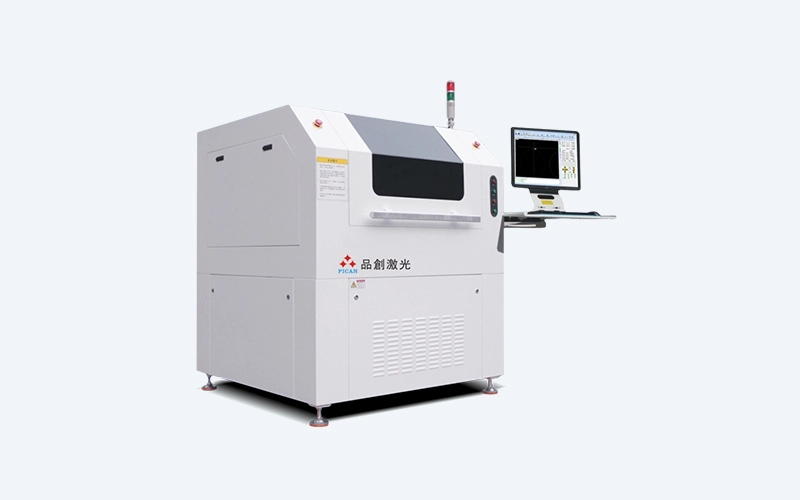

The medical device and medical consumables industry has maintained steady growth in recent years. With increasingly stringent regulatory standards and the accelerating trend towards precision in medical equipment, the manufacturing sector is undergoing a comprehensive digital and automated upgrade. Laser processing technology, due to its high cleanliness, high precision, and strong controllability, is becoming an important driving force in medical manufacturing.

In medical device manufacturing, laser cutting and welding can be applied to the sealing and processing of stainless steel surgical instruments, minimally invasive surgical tools, implants, catheters, needles, and plastic consumables. Compared with traditional processes, lasers can achieve burr-free, non-contact, and minimally invasive edge processing, greatly reducing contamination risks and enhancing product reliability.

As global requirements for medical safety standards (such as ISO 13485) become increasingly stringent, more and more medical manufacturing companies are choosing to adopt automated laser equipment and vision inspection systems to improve production quality and consistency. Market research predicts that the global medical laser processing market will exceed US$12 billion by 2025, and lasers will become an important force driving the modernization of medical manufacturing.