NEWS

Corporate News, Industry Information

Laser Precision Processing Drives 3C Electronics Lightweighting

Against the backdrop of increasingly fierce competition in the global consumer electronics market, products such as mobile phones, tablets, laptops, and smart wearables are rapidly iterating towards being thinner, lighter, more integrated, and more precise, which directly drives up the demand for precision laser processing in the industry chain.

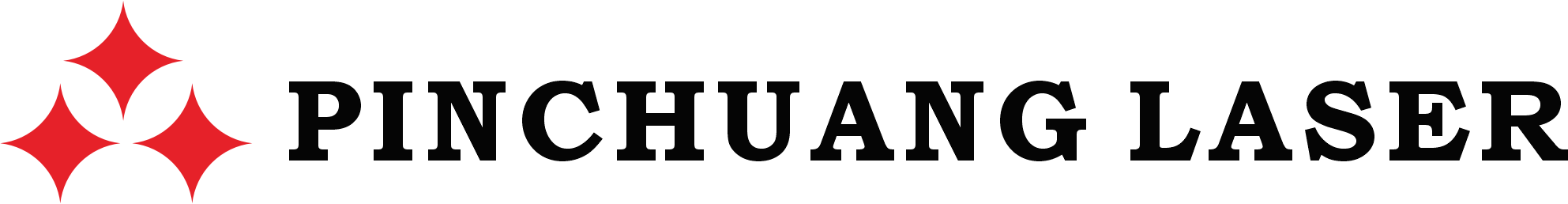

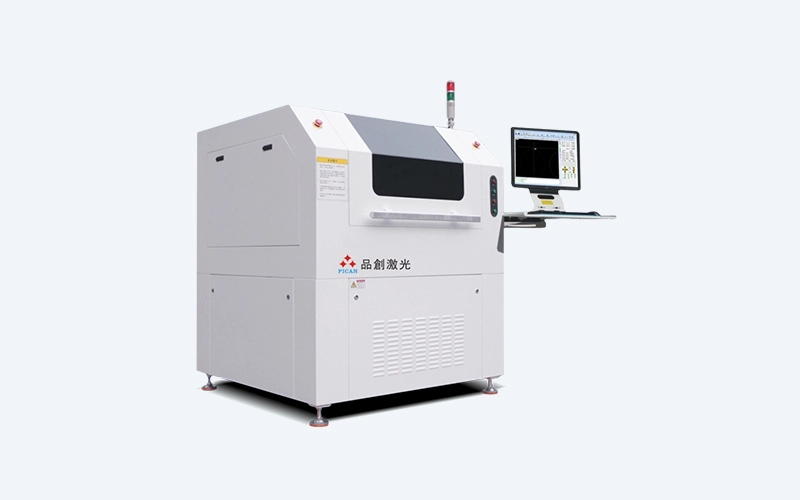

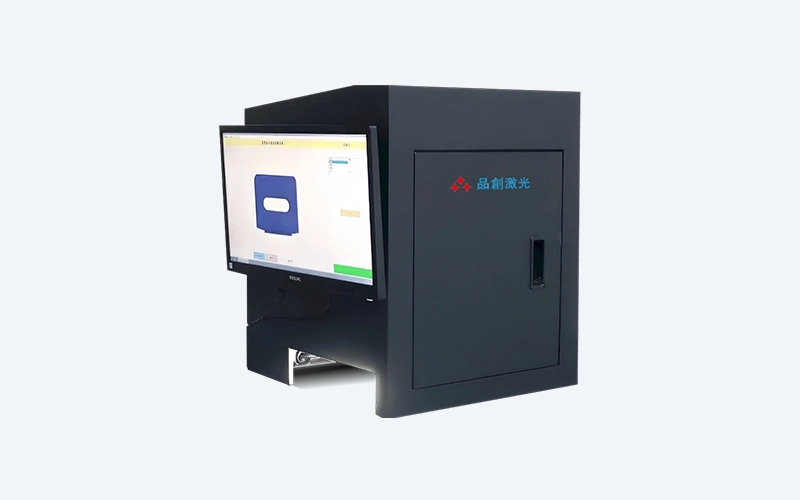

Laser cutting, laser micro-hole processing, ultra-precision welding, and laser marking are becoming fundamental processes in 3C manufacturing. In particular, laser technology continues to expand its application scope in the micro-hole processing of metal frames, metal back covers, glass covers, flexible printed circuit boards (FPCs), and structural components due to its non-contact, low heat-affected zone, and mass production capabilities.

According to industry research reports, the 3C laser processing market is expected to exceed 50 billion yuan in the next two years. The rise of emerging products such as AI smartphones, foldable screen devices, and smart head-mounted displays (XR) is also creating new demand for high-precision laser equipment. As consumer electronics products become more complex and have stricter tolerances, the value of laser processing in improving product consistency, reliability, and appearance precision will become even more prominent.