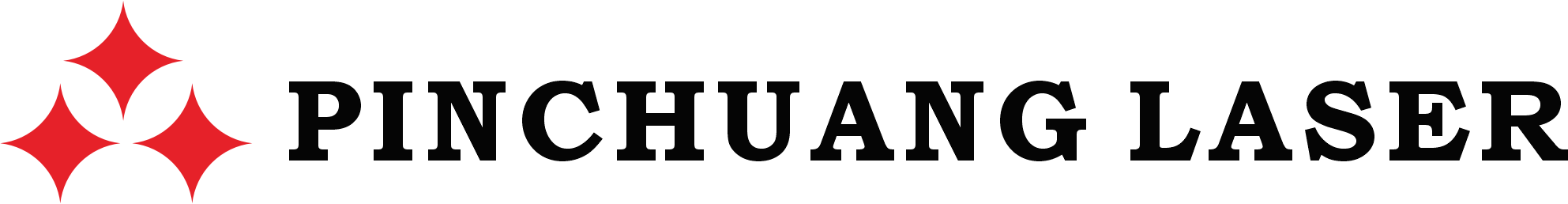

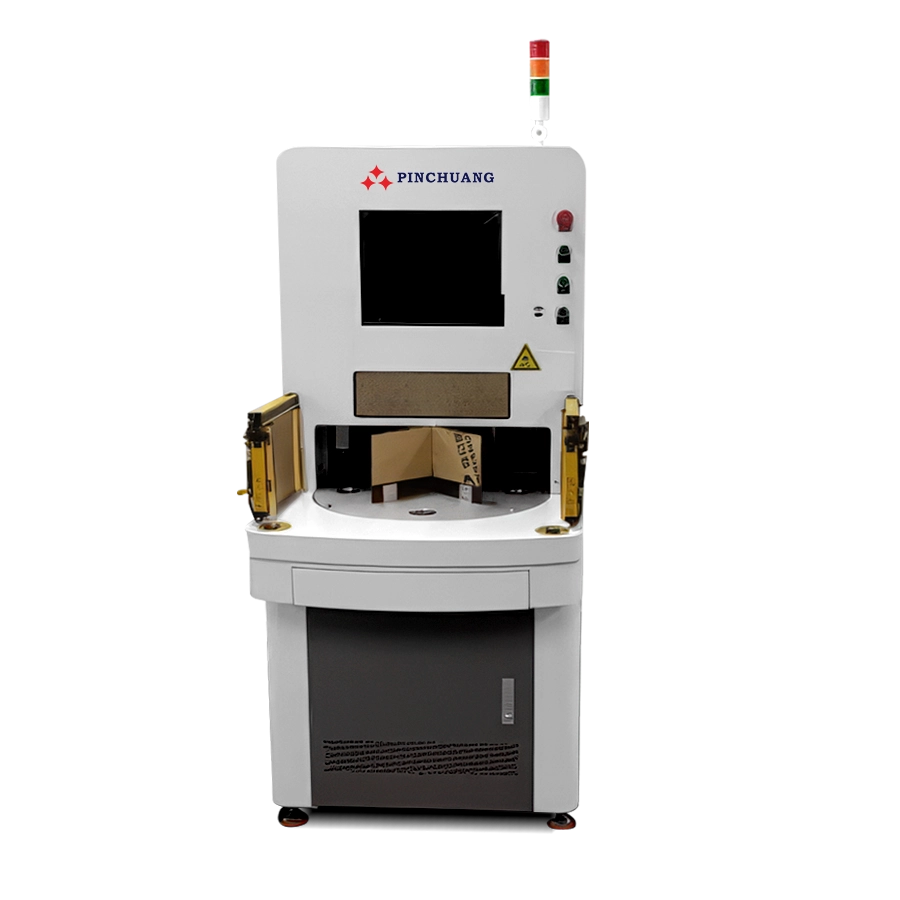

Four-station ultraviolet laser marking system

The four-station laser marking system is an automated marking device based on a high-efficiency rotary table design. Its core advantage lies in the simultaneous operation of loading, marking, and unloading processes through multiple stations in a cyclical manner, increasing production efficiency several times that of traditional single-station equipment. The system supports flexible customization of the number of stations (such as two-station or four-station) according to your specific production volume and process requirements. It features high marking accuracy, stable operation, and good integration, and is specifically designed to meet the marking needs of high-volume, high-intensity continuous production lines in industries such as electronic components, hardware tools, and medical devices.

Product Advantages

01

- Increased efficiency: Multi-station synchronous operation enables loading, marking, and unloading to be carried out in parallel, resulting in production efficiency several times that of traditional single-station equipment.

- Flexible customization: The number of workstations of different grades, such as grade 2 and grade 4, can be flexibly customized according to your production needs, perfectly adapting to diverse production scenarios.

- Precise and stable: High marking accuracy and stable and reliable operation ensure excellent product yield even under continuous high-intensity production.

- Professional and efficient: Designed specifically for the high-volume marking needs of industries such as electronic components, medical devices, and hardware tools, it is an ideal solution to enhance the competitiveness of production lines.

Sample Show

02

Product Specifications

03

| Item | Specification Parameters |

|---|---|

| Lasser Wavelength | 355nm |

| Laser power | 5W/10W (optional) |

| Pulse frequency | 30-150KHz |

| Marking range | 100mm*100mm / 150mm*150mm (optional) |

| pulse width | <15ns |

| Output power instability | <3% |

| Engraving depth | ≤0.4mm |

| Engraving line speed | ≤7000mm/s |

| Minimum Line Width | 0.02mm |

| Repeat Accuracy | ±0.003mm |

| Minimum characters | 0.3mm |

| cooling method | Water cooling |

| Power supply | 220V±5%, 50Hz/16A |

| Overall Dimension | 1440mm(L)×760mm(W)×1995mm(H) |

| Ambient Temperature | 0~40°C,if out ofrange, air conditioning is required |