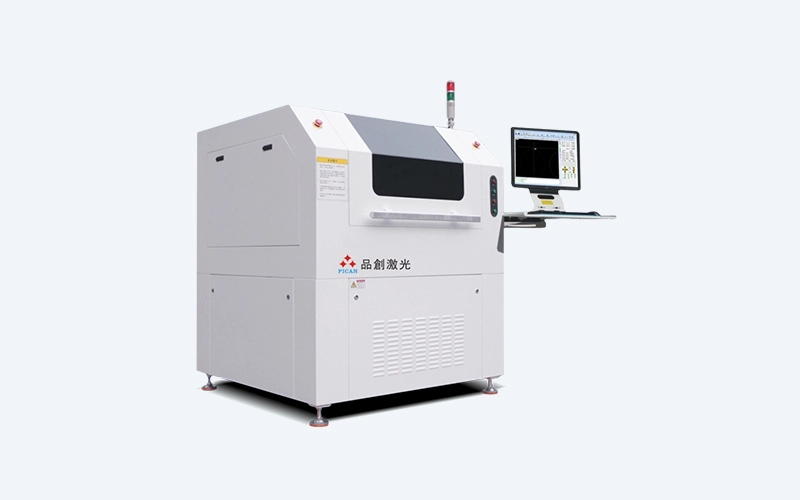

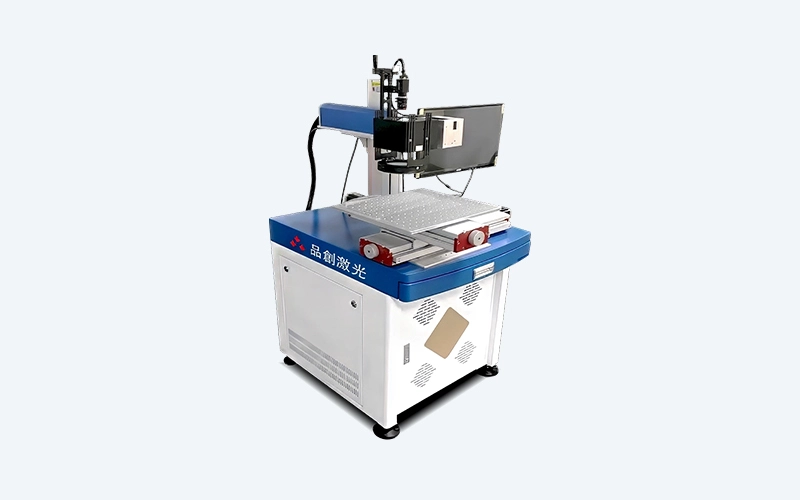

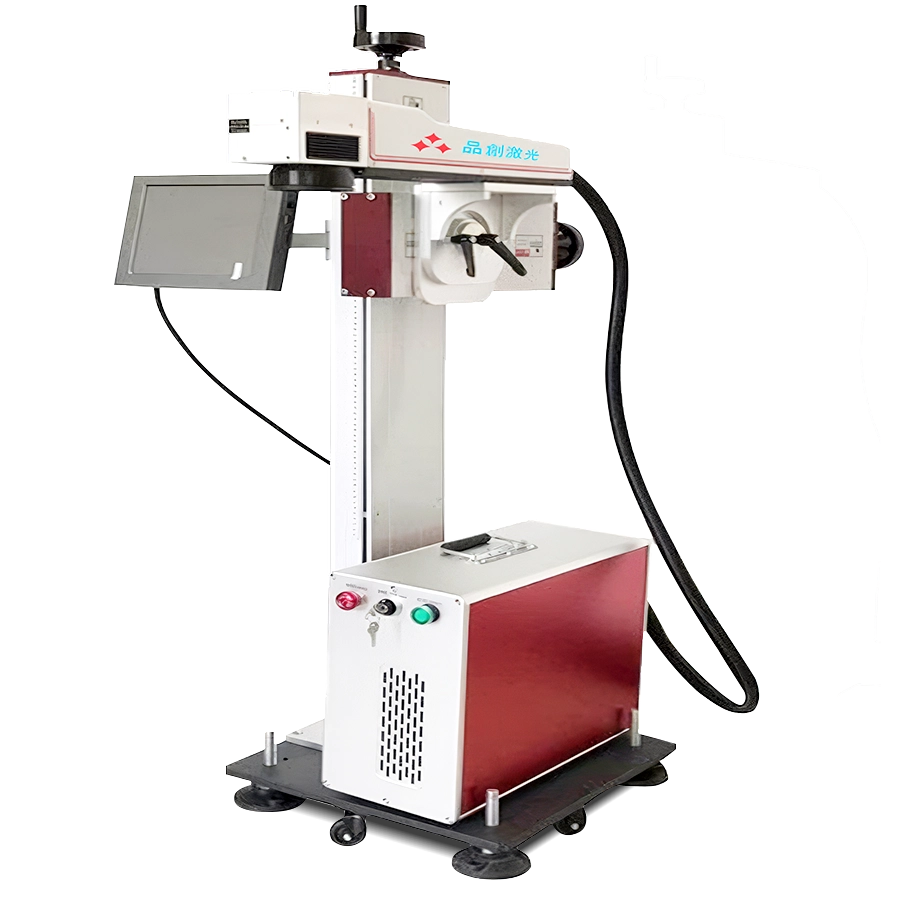

Laser marking and marking system

Laser marking systems are advanced non-contact marking devices that use high-energy laser beams to achieve permanent, high-definition markings on the surfaces of various products. These systems are widely used in industries such as food, beverages, dairy products, electronic components, and pharmaceutical packaging, meeting the needs for marking graphic and textual information such as production dates, batch numbers, shifts, manufacturer logos, serial numbers, and QR codes. They are key equipment for product traceability, anti-counterfeiting, brand display, and lean management.

Product Advantages

01

- High-speed marking: Utilizing a high-performance galvanometer, it achieves marking speeds of tens of thousands of millimeters per second, meeting the online marking requirements of high-speed production lines.

- Permanent marking: The marking is clear and durable, and can display characters from millimeters to micrometers. It is tamper-proof, ensuring traceability and anti-counterfeiting.

- Wide applicability: No ink required, enabling high-quality marking on a variety of materials including plastic, glass, metal, and paper.

- Rugged and durable: Industrial-grade design, compact structure, high stability, and able to adapt to harsh environments such as humid conditions.

Sample Show

02

Product Specifications

03

| Item | Specification Parameters | |

|---|---|---|

| Lasser Wavelength | 1064nm | 10. 6um |

| Laser power | 20W/30W/50W/60W (optional) | 30W/60W (optional) |

| Pulse frequency | 20-200KHz | 1-25KHz |

| Marking range | 100mm*100mm / 150mm*150mm (optional) | |

| Standard Working Distance | 152mm/216mm | |

| Scanning Speed | ≤7000mm/s | |

| Minimum Line Width | 0.06mm (depending on material) | |

| Minimum Character Size | 0.2mm | |

| Repeat Accuracy | ±0.05mm | |

| cooling method | Water cooling/air cooling | |

| Power supply | 1.0KW/220V/Single Phase/50Hz/10A (Voltage Fluctuation <±5%) | |

| Overall Dimension | 450mm(L)×320mm(W)×650mm(H) | |

| Ambient Temperature | 15~35°C,if out ofrange, air conditioning is required | |