solutions

Solutions

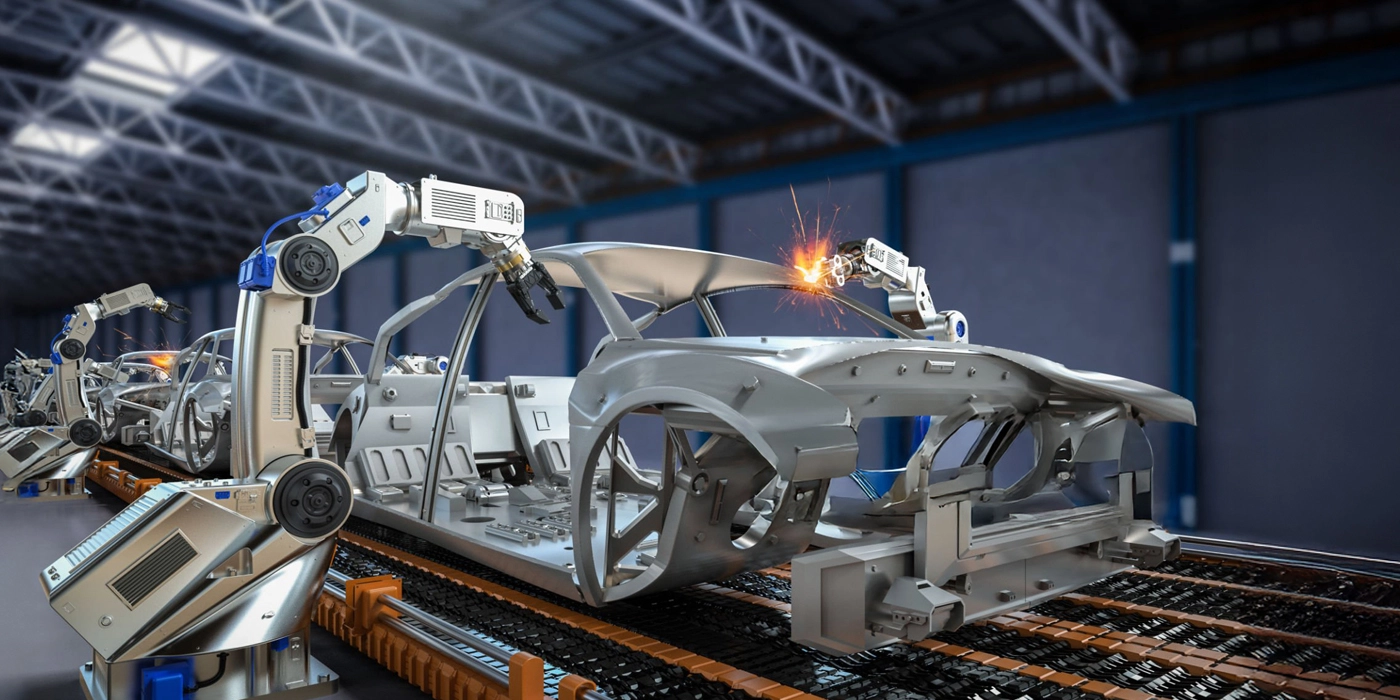

Automobile Manufacturing

Solution introduction

In the automotive manufacturing sector, laser technology has become a key force in enhancing production efficiency and precision. Our laser cutting, welding, and marking equipment is widely used in the processing of body structural components, powertrain systems, battery modules, and interior and exterior parts, delivering high-speed, high-precision, burr-free results. Supported by intelligent vision systems for positioning and inspection, we help automotive manufacturers improve consistency, reduce production costs, and meet the lightweight and high-safety manufacturing requirements of new energy vehicles.

Hydrogen energy

The hydrogen energy industry demands extremely high precision, particularly in the processing of fuel cell bipolar plates, stack components, and sealing parts, where airtightness, weld consistency, and corrosion resistance are critical. We focus on core fuel cell components, delivering intelligent laser manufacturing solutions for challenging processes such as bipolar plate cutting, dual-seam overlap welding, micro-channel welding, and thin metal sheet forming.

Using high-brightness fiber lasers and high-speed galvanometer control, our solutions achieve large-area, high-precision, burr-free cutting. Proprietary gas-tight welding, combined with vision positioning and intelligent process monitoring, ensures full-process quality control and improved consistency and reliability of fuel cell stack production—supporting the hydrogen energy industry’s shift toward higher efficiency and lower energy consumption.

Lithium battery

With the rapid growth of new energy power systems, lithium battery structural components face increasingly stringent requirements for safety, precision, and consistency. Aligned with innovations in battery structures, we focus on core processes such as cover plates, cell welding, and current collector processing, delivering fully automated production from loading, cleaning, coating removal, laser welding, and leak testing to final inspection and packaging.

For cylindrical, prismatic, and pouch batteries, we provide highly integrated automated laser production lines covering tab welding, housing cutting, cover plate welding, molded structural component processing, and sealing welding. Leveraging a dual closed-loop control system combining laser and vision technologies, welding defect rates are reduced to industry-leading levels, while overall line efficiency is increased by 30–60%, helping customers enhance battery safety, reduce production costs, and accelerate time to market.

Automotive electronics

Amid the rapid evolution of automotive electronics, laser processing has become a core technology for enabling lightweight, miniaturized, and highly reliable products. Leveraging expertise in laser cutting, welding, marking, and vision inspection, we overcome traditional manufacturing limitations through process innovation, supporting high-quality upgrades for automotive control systems, electric drive systems, and power devices.

To meet the stringent automotive-grade requirements for thermal performance, high density, and consistency, we deliver integrated solutions covering laser welding, precision coating removal, micro-cutting, fine marking, automated assembly, and multi-dimensional vision inspection. Powered by proprietary high-stability laser processes and an intelligent process database, our solutions achieve industry-leading welding yields, improve production efficiency by over 40%, and significantly reduce labor and process costs—helping customers gain a competitive edge in the era of automotive electrification.