FAQ

FAQ

Access expert insights, case studies, and automation solutions

FAQ

What are the main applications of laser processing in the 3C electronics industry?

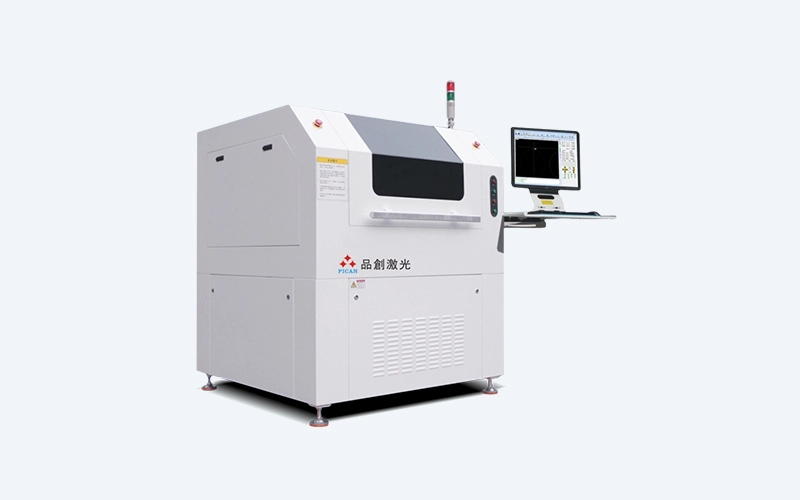

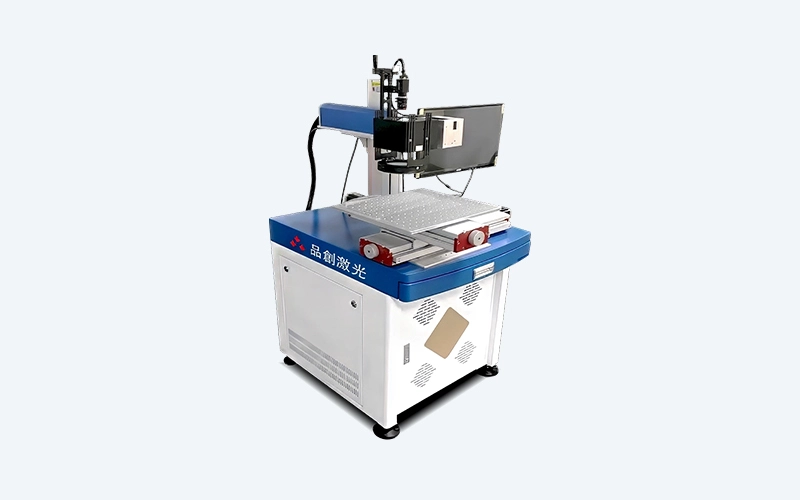

Laser technology is widely used in various processes such as cutting metal frames for mobile phones, cutting glass covers, cutting FPC flexible circuit boards, marking metal shells, processing camera modules, and welding battery structural components, which can meet the manufacturing needs of high precision and miniaturization.

What level of precision can laser processing achieve?

Depending on the equipment and materials used, laser micromachining can achieve... ±0.01mm With higher processing precision, it is ideal for manufacturing precision structural components and micro-processes for 3C products.

Will laser processing cause thermal damage to products?

Our laser systems use High energy density focusing, small heat-affected zone The process design, combined with visual assistance, enables stable non-contact processing, thereby effectively avoiding problems such as edge scorching and thermal deformation.

What are the advantages of laser cutting compared to traditional tool cutting?

Laser cutting has the following significant advantages:

Non-contact processing, no material abrasion

The cut is smooth and requires no secondary polishing.

Supports complex curves and microstructures

Fast and efficient

Suitable for flexible and irregularly shaped materials

Therefore, laser technology has become the mainstream processing method in the 3C industry.

Are laser devices compatible with automated production lines?

Yes. Our system supports... Robots, conveyor lines, CCD vision positioning, MES system With high integration, it can build fully automated production lines that meet the needs of the 3C industry.